In industrial processes where the separation of liquids, solids, and gases is critical, filter separators play a vital role. These highly effective devices are designed to remove impurities and contaminants from the process stream, ensuring optimal performance and safeguarding equipment integrity. In this article, we will delve into the concept of a filter separator, explore its functionality, and highlight its significance in achieving efficient industrial filtration.

Understanding the Filter Separator

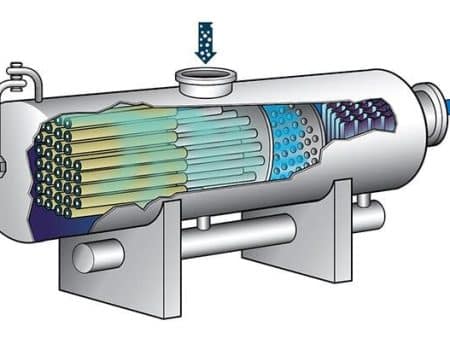

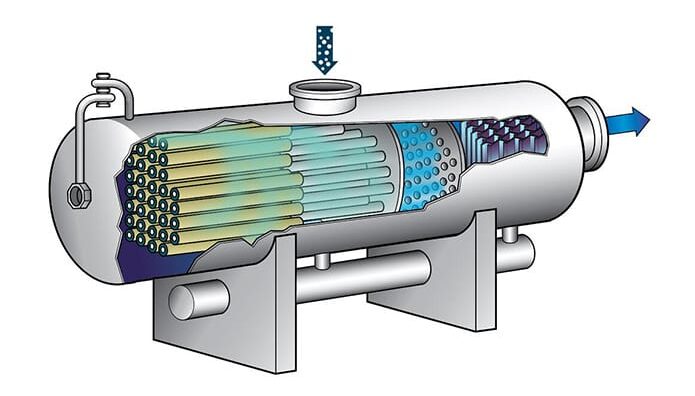

A filter separator is a specialized piece of equipment utilized in industrial settings to remove solid and liquid contaminants from gases or liquids. It operates on the principle of filtration, employing various filter media to capture and separate particles, solids, and liquids of different sizes. The filter separator typically consists of a vessel housing the filter elements, an inlet for the contaminated stream, and separate outlets for the clean gas or liquid and the collected contaminants.

Key Functionality of Filter Separators

The primary function of a filter separator is to efficiently remove impurities and contaminants from process streams. It achieves this through several key processes:

Filtration: The filter separator employs a range of filter media, such as mesh screens, porous membranes, or pleated cartridges, to physically trap and retain particles and solids of varying sizes.

Separation: The filter separator allows for the separation of liquids and solids from gases or liquids, preventing them from entering downstream equipment and causing damage or operational issues.

Contaminant Collection: As the process stream flows through the filter separator, the captured contaminants accumulate within the vessel. Periodic maintenance and cleaning of the separator are necessary to remove the collected impurities.

Significance in Industrial Filtration

Filter separators are crucial components in numerous industrial applications where the presence of contaminants can compromise product quality, equipment functionality, and overall process efficiency. They find extensive use in oil and gas production, petrochemical refineries, pharmaceutical manufacturing, power generation, and wastewater treatment, among others. By removing harmful particulates, liquids, and solids, filter separators ensure the integrity of downstream equipment, enhance operational safety, and minimize the risk of process disruptions and costly repairs.

Types of Filter Separators

Filter separators are available in various configurations to suit different application requirements. Some common types include:

Gas Filter Separators: Specifically designed for gas filtration, these separators are utilized in gas processing plants, natural gas pipelines, and compression stations.

Liquid Filter Separators: Primarily used in liquid processing industries such as chemical manufacturing and wastewater treatment, these separators effectively remove contaminants from liquids.

Coalescing Filter Separators: These separators focus on removing liquid droplets and aerosols from gas streams by employing coalescing filter media.

Filter separators are indispensable in industrial filtration systems, ensuring the efficient removal of impurities and contaminants from process streams. By employing various filter media and separation mechanisms, these devices safeguard equipment integrity, enhance operational efficiency, and uphold product quality. Whether it’s in the oil and gas industry or pharmaceutical manufacturing, filter separators play a crucial role in maintaining clean and reliable process streams. To benefit from the advantages of a filter separator tailored to your specific needs, consult with filtration experts like CECO Environmental, who offer a wide range of innovative filtration solutions.