In the realm of industrial air pollution control, thermal oxidizers stand out as indispensable devices designed to tackle emissions effectively. Their use helps companies not only protect the environment but also meet regulatory compliance. This introductory guide aims to shed light on the fundamental aspects of thermal oxidizers, their types, and the many benefits they offer to diverse industries.

Understanding Thermal Oxidizers

Thermal oxidizers are advanced air pollution control systems engineered to neutralize harmful pollutants emitted during industrial processes. They operate on the principle of combustion, using elevated temperatures to oxidize and eliminate volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other contaminants present in industrial exhaust gases.

Different Types of Thermal Oxidizers

-

Direct-Fired Thermal Oxidizers (DFTOs):

- DFTOs burn pollutants directly in the combustion chamber, making them suitable for applications with high concentrations of contaminants.

- High-temperature destruction: DTFOs can treat a wide range of hazardous waste streams by incinerating them at extremely high temperatures, typically exceeding 1,200°C (2,200°F). This process effectively destroys organic and inorganic contaminants, reducing them to harmless byproducts like water vapor and carbon dioxide.

- Air pollution control: DTFOs are equipped with emission control systems to minimize air pollution. These systems can include scrubbers, baghouses, and catalytic converters to remove harmful pollutants like dioxins, furans, and heavy metals from the exhaust gases.

- Waste volume reduction: DTFOs significantly reduce the volume of hazardous waste compared to other treatment methods like landfill disposal. This can lead to significant cost savings and environmental benefits.

- Fuel efficiency: Some DTFOs can utilize the heat generated from the incineration process to partially or completely self-sustain their operation, reducing the need for additional fuel and lowering overall operating costs.

- Wide range of applications: DTFOs are used in various industries for treating hazardous waste, including chemical manufacturing, pharmaceutical production, petroleum refining, metal processing, and waste management facilities.

-

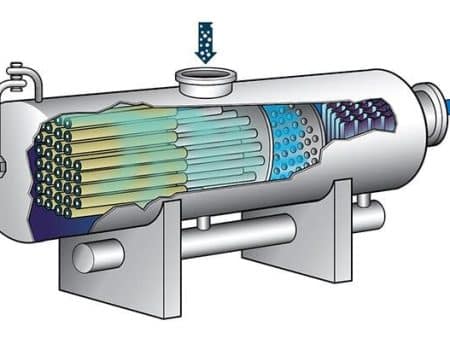

Regenerative Thermal Oxidizers (RTOs):

- Regenerative Thermal Oxidizers use a regenerative heat exchanger to preheat incoming pollutants, enhancing energy efficiency by recovering heat from the combustion process

- Regenerative Thermal Oxidizers are specialized operating systems designed for real-time applications where tasks have strict timing constraints. These applications must respond to events and complete tasks within predefined deadlines, often in milliseconds or even microseconds.

- RTOs provide predictable and deterministic behavior. This means you can know exactly how long a task will take to complete and guarantee it will always produce the same result. This is crucial for ensuring timely responses in real-time systems.

- RTOs use priority scheduling to ensure that critical tasks are always executed first. This helps to meet deadlines and avoid system failures.

- RTOs have a small footprint and minimal resource requirements compared to general-purpose operating systems. This makes them suitable for resource-constrained embedded systems.

-

Catalytic Thermal Oxidizers (CTOs):

- CTOs employ catalysts to facilitate lower-temperature combustion, reducing energy consumption and operational costs.

Benefits of Thermal Oxidizers

- Emission Reduction: Thermal oxidizers excel in minimizing emissions of harmful pollutants, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

- Energy Recovery: Certain types, like RTOs, incorporate heat recovery systems, allowing industries to reclaim and reuse thermal energy generated during the oxidation process, leading to significant energy savings.

- Versatility:Thermal oxidizers are versatile solutions applicable across various industries, including chemical manufacturing, pharmaceuticals, and food processing, offering tailored approaches to diverse emission challenges.

Choosing the Right Thermal Oxidizer Solution

Selecting the optimal thermal oxidizer solution for your specific industry and application is crucial. To explore the right thermal oxidizer solution for your specific requirements, reach out to CECO today and take the first step toward a cleaner, greener future for your industrial operations.