In today’s dynamic industrial landscape, where operational efficiency and environmental responsibility are intertwined, industrial cyclone separators play a crucial role. These engineered devices effectively remove unwanted particles from air streams, safeguarding both employee health and equipment performance. Their deceptively simple design belies the complex principles governing their operation, making them a cornerstone of numerous industrial processes. This article delves into the science behind cyclone separators, highlighting their diverse applications and technical considerations.

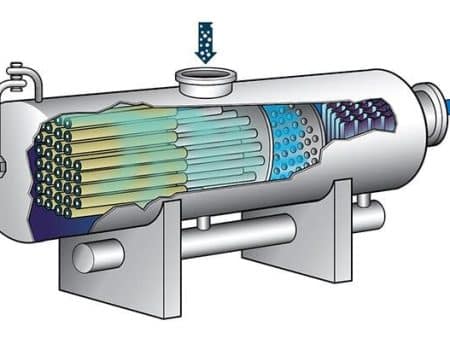

How Industrial Cyclone Separators Work: Leveraging Centrifugal Forces

The fundamental principle underpinning cyclone separators lies in the utilization of centrifugal forces. As gas laden with dust or other particles enters tangentially into the cylindrical chamber, it’s forced into a high-velocity spiral due to the specific inlet design. This swirling motion generates powerful centrifugal forces, which propel heavier particles outward towards the conical walls. These expelled particles then spiral down along the conical surface and collect in a dedicated hopper at the bottom, effectively separated from the air stream. Meanwhile, the cleansed gas, devoid of its unwanted burden, rises in the center and exits through the top, leaving behind a concentrated mass of separated material for potential reprocessing or responsible disposal.

Types of Industrial Cyclone Separators: Catering to Specific Needs

Industrial cyclone separators are not a monolithic solution. Different types cater to specific particle sizes and capture efficiency requirements:

- Standard Cyclones: These workhorses of the industry excel at general dust collection and handling larger particles like sawdust or metal shavings. Their tangential inlet and moderate conical angle result in cost-effective and easy-to-maintain solutions for basic dust control needs.

- High-Efficiency Cyclones: When finer dust particles in the 5-10 micron range necessitate capture, these advanced designs boast superior separation efficiency. Employing sophisticated internal geometries and steeper conical angles, they generate more intense vortices, significantly enhancing their ability to capture even the most elusive dust motes. Their targeted efficiency comes at a cost – higher initial investment and potentially more complex maintenance – but for industries like pharmaceuticals and electronics where fine dust control is paramount, the trade-off is often justified.

- Multi-Cyclone Separators: For high-volume applications where sheer airflow and dust loads are prevalent, multi-cyclone separators offer a formidable solution. These systems combine multiple standard cyclones within a single unit, each contributing to the collective task of tackling massive airflows and dust loads. This approach finds favor in industries like power generation and cement manufacturing, where dust control is both a safety and environmental imperative.

Material Considerations: Optimizing Performance and Longevity

Material selection plays a pivotal role in the performance and lifespan of cyclone separators. While robust steel construction remains the preferred choice for standard applications due to its cost-effectiveness, high-efficiency cyclones might utilize wear-resistant ceramics or specialized coatings to withstand abrasive dust challenges. For applications involving hot gases or corrosive materials, stainless steel becomes the material of choice, ensuring structural integrity and optimal dust capture.

Industrial Cyclone Separators: Pillars of a Sustainable Future

Industrial cyclone separators represent more than just dust control devices; they are cornerstones of a sustainable industrial future. Their ability to safeguard employee well-being, protect equipment, and minimize environmental impact makes them critical components of responsible and efficient industrial operations. Understanding the science and capabilities of these versatile devices empowers businesses to select the optimal cyclone separator for their specific needs, contributing to a cleaner and more sustainable industrial landscape.

Choosing the Right Cyclone Separator:

With so many industrial cyclone options available it is challenging to select the one most appropriate for your needs and application. Particle size, desired efficiency, gas flow rate, and your budget all determine which industrial cyclone separator is the most suitable for you.

Consult with one of CECO’s many industrial cyclone experts to ensure you invest in the perfect cyclone for your unique needs.