In today’s industrial landscape, environmental regulations and air quality concerns are paramount. Wet scrubbers have emerged as a crucial solution for industries seeking to control air pollution and reduce harmful emissions. This comprehensive guide will delve into the world of wet scrubbers, exploring their inner workings and highlighting the reasons why your facility should consider implementing one.

What is a Wet Scrubber?

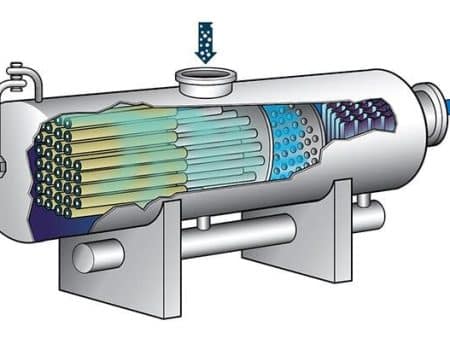

A wet scrubber is an air pollution control device that efficiently removes pollutants from industrial exhaust gases. It operates on the principle of using a liquid (usually water or a chemical solution) to trap and neutralize harmful pollutants before they are released into the atmosphere. Wet scrubbers are highly effective in capturing various pollutants, including particulate matter, sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs). Learn more about “what is a wet scrubber”.

How Do Wet Scrubbers Work?

Particle Capture

The first stage of a wet scrubber’s operation involves capturing and removing particulate matter from the exhaust gas. As the contaminated gas enters the scrubber, it passes through a series of water droplets or a wetted surface. The particles in the gas collide with the liquid, causing them to adhere to the droplets’ surface. Gravity then pulls these laden droplets down into a collection area, effectively removing the particles from the gas stream.

Gas-Absorption

In the gas-absorption stage, wet scrubbers target gaseous pollutants such as SO2 and NOx. The contaminated gas is brought into contact with the scrubbing liquid, which chemically reacts with the pollutants to neutralize them. This reaction converts harmful gases into harmless compounds, making them safe for release into the environment. Learn more about gas wet scrubbers.

Types of Wet Scrubbers

Venturi Scrubbers

Venturi scrubbers utilize a converging-diverging section to create a high-velocity throat that generates turbulence and increases contact between the gas and the scrubbing liquid. This design maximizes particle capture efficiency and is particularly effective for fine particulate matter.

Packed Bed Scrubbers

Packed bed scrubbers consist of layers of packing material (such as plastic or metal) that provide a large surface area for gas-liquid contact. Pollutants are absorbed as they pass through the packed bed, ensuring efficient removal of gaseous contaminants.

Spray Tower Scrubbers

Spray tower scrubbers work by spraying the scrubbing liquid from the top of a tower, while the contaminated gas enters from the bottom and flows upwards. This counter-current flow enhances gas-liquid contact, resulting in effective pollutant removal.

The Importance of Wet Scrubbers in Industrial Settings

Regulatory Compliance

One of the primary reasons to invest in a wet scrubber is to ensure compliance with environmental regulations. Governments impose strict emissions standards, and non-compliance can lead to hefty fines and legal issues. A well-maintained wet scrubber helps industries meet these standards, avoiding potential penalties.

Protecting Public Health

Harmful pollutants emitted from industrial processes can have severe health consequences for nearby communities. Wet scrubbers play a vital role in minimizing these emissions, protecting public health, and contributing to cleaner air for everyone.

Preserving the Environment

Air pollution not only affects human health but also leads to environmental degradation. Wet scrubbers aid in preserving ecosystems, reducing acid rain formation, and mitigating the adverse effects of pollution on vegetation and wildlife.

Implementing a wet scrubber in your industrial facility is a wise and responsible decision. Not only does it enhance regulatory compliance, but it also demonstrates a commitment to environmental stewardship and public health. Choose the right type of wet scrubber based on your specific needs and enjoy the benefits of cleaner air and a greener future.