Corrosion resistance Pumps FRP Fiberglass Reinforced Plastic Pump

Many industries require fluid-handling management, with mission-critical applications specific to each type of fluid. The corrosive levels of an application may vary, but all require pumping equipment to manage them. Industries from wastewater desalination and petrochemical to scrubber and odor control must have a pump that is corrosion resistant, offering durability and reliability. One type of pump that is designed to be extremely corrosive resistant is a Fiberglass Reinforced Polymer (FRP) centrifugal pump designed by Fybroc, a CECO Environmental brand.

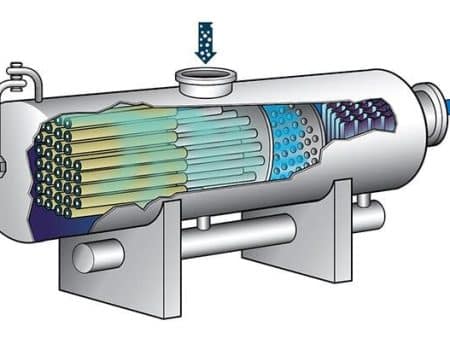

Fybroc’s FRP technology, which dates back to the mid-60s, offers two unique elements, among others: an integral, a one-piece impeller and shaft sleeve and a dual volute casing.

The one-piece impeller and shaft sleeve eliminates the potential of damaging leakage past shaft sleeve O-rings and prevents any process fluid from coming in contact with the shaft. The dual volute casing maximizes mechanical seal and bearing life. This effectively means Fybroc fiberglass pumps have exceptional structural integrity, excellent corrosion resistance and dependable service in difficult operating environments. There are a host of other configurations for various applications including:

- Horizontal ANSI

- Self-priming

- Vertical sump & cantilever

- Recessed impeller

- Close-coupled

- Sealless mag-drive

The fiberglass components are manufactured utilizing a Resin Transfer Molding (RTM) technique. Using vinyl ester resin (which handles a large portion of industry needs), or VR-1, which is one of many construction materials that are available, FRP pumps have a heightened level of corrosive protection. We will further discuss the value of VR-1 based resin later.

CECO Fybroc also offer pumps in many different materials, such as a synthetic veil for resistance to hydrofluoric acid, an abrasive resistant material for liquids containing abrasive fines, a special BPO/DMA cure system for handling sodium hypochlorite (bleach), and epoxy for outstanding resistance to aggressive solvents.

Pump Design for Use

One industry that heavily relies on fiberglass pumps like this is aquariums. Due to high levels of salt water and other corrosive materials flowing through the facility/exhibits, they require pumps that can withstand the harshest conditions. Having the right “life support system” means cleaning, treating and conditioning the water.

FRP Pumps keep the heartbeat of an aquarium strong, ensuring marine life are protected from harm, while introducing, filtering and recirculating the salt water. Primary advantages include absolutely no corrosion and no leaching of harmful minerals into the exhibit environment. Customers also desire an efficient system with beneficial long-term lifecycle costs, which are just a few additional reasons why customers in the aquarium industry utilize Fybroc FRP pumps.

However, there are various elements, or design features, typically incorporated into pumps for each aquarium customer application. These elements and accompanying data allow CECO engineers to provide optimal data-driven recommendations to achieve the desired results for customer’s specific needs and goals.

Customer Case Study

A leading supplier of acid- and caustic-based industrial water treatment products contacted CECO Fybroc to help with an aging infrastructure of pumps. The determination was to replace all the pumps to improve manufacturing productivity and enable a higher volume of orders to be met within established service levels.

The pumps that facilitate the customer’s processes needed to be quickly removed, reset and reinstalled in order to drastically limit down time. However, before contacting CECO Fybroc, the customer first did extensive due diligence to determine the best company and product to meet their needs. They tested the options available on the market against criteria including compatibilities, flow rate, reliability and manufacturer turnaround time.

After choosing Fybroc, the scope of the project and plan were put into motion. They went with the Fybroc 2530, which is a one-piece molded thermoset construction sealless mag-drive pump. This pump has no welded, sealed or lined parts, which provides quality chemical compatibilities while resisting internal and external corrosion. As a result, the pump was able to handle the roughly 55 acid- and caustic-based raw materials in the company’s manufacturing process.

Within the first eight months after installation, the customer was able to reclaim their investment, increase productivity, reduce hours for preventative maintenance, as well as reduce downtime by about 80%.

Value of an FRP Pump System

Many pumps throughout the industry are made with other exotic alloy (metallic) materials. When metallic pumps are used there are many types (general/localized/galvanic) of corrosion that can occur in varying degrees depending on the type of metal selected. The Fybroc FRP pumps are a unique fit for these applications and offer many advantages over these other types of pumps normally required for these aggressive, corrosive applications. Advantages include no corrosion, no metallic parts in contact with the fluid being pumped, lower cost, lighter weight, and dramatically improved service lifetimes.

Expanding on the VR-1 base resin referenced above, the RTM process allows for the controlled placement of continuous-strand fiberglass mat in high stress areas. The major advantage of this process, unlike a compression molded process that inherently uses randomly oriented pieces of chopped fiberglass leading to comparatively lower strength, is that the carefully oriented continuous-strand fiberglass mat provides components with excellent physical strength and properties. In addition, the process allows for the design of thinner walled structures, thereby permitting the use of nearly pure resin systems for optimum corrosion resistance.

Simply put: Fiberglass adds the strength, and the resin (VR-1) adds the corrosion resistance, optimizing both in the manufacturing process.

What does this mean? It means that you will find Fybroc pumps hard at work anywhere corrosive acids, bleach, caustics, saltwater, wastewater, abrasive fines, and aggressive solvents are transferred. The FRP pumps give customers peace-of-mind that they will realize lower total cost of ownership, increased pump efficiency, high quality and high durability that can be relied on.

CECO Fybroc also manufactures fiberglass baseplates, a value-added option since chemical pumps are often used and installed in environments where external corrosion can be a major problem.

Other Applications and Systems

CECO continues to work on developing environmentally friendly solutions. With the growing awareness of the significance of clean air and clean water, there continues to be an increased use of nonmetallic FRP pumps in a variety of applications. These include, among others, scrubbing systems for odor control and chemical feeding systems for enhanced coagulation, both seen in industrial and municipal wastewater treatment plants that require chemical recirculation and transfer pumps.

CECO Fybroc is the world leader in the design and production of FRP pumps for corrosive and other difficult liquids. The pumps provide years of dependable service in the most extreme service applications and are among the highest in energy efficiency in the applications and industries we serve, which translates to one of the lowest life cycle costs available across our customer base.