Air pollution control systems are essential for industries to comply with environmental regulations and protect the environment. Among these systems, Regenerative Thermal Oxidizers (RTOs) stand out for their efficiency and cost-effectiveness. This article explores how RTOs compare to other air pollution control systems in terms of performance and cost, focusing on their application in various industries.

Understanding RTOs

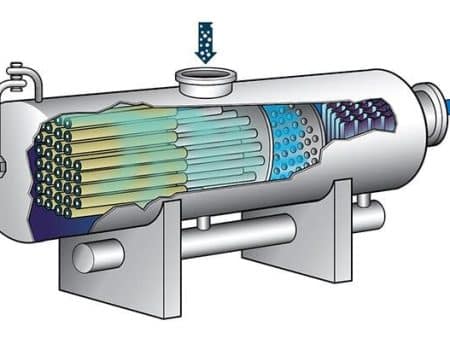

Regenerative Thermal Oxidizers (RTOs) are designed to destroy volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) through thermal oxidation. The Adwest RETOX Tower-Type RTO system, for example, offers multi-tower technology that provides up to 99%+ emission reductions of VOCs, acids, and malodorous process streams. The system uses ceramic media beds to achieve up to 97% primary heat recovery, making it highly efficient.

Performance Comparison

Efficiency in Emission Reduction

-

RTOs: RTOs are known for their high efficiency in reducing emissions. The multi-tower technology in Adwest RTOs can achieve up to 99%+ reduction of VOCs. This high level of efficiency is due to the thermal regeneration process, which preheats the polluted air to near oxidation temperatures, ensuring complete combustion with minimal auxiliary fuel.

-

Catalytic Oxidizers: These systems also provide high VOC destruction efficiency (typically 95-99%). However, they rely on catalysts to lower the oxidation temperature, which can be susceptible to poisoning by certain compounds.

-

Biofilters: While biofilters are effective in treating VOCs and odors, their efficiency can vary based on the type of pollutants and operating conditions. Typically, they achieve 70-90% removal efficiency.

Heat Recovery and Energy Efficiency

-

RTOs: RTOs excel in heat recovery, with the Adwest RTO system recovering up to 97% of the heat. This high heat recovery rate significantly reduces the need for additional fuel, making RTOs more energy-efficient.

-

Catalytic Oxidizers: These systems have lower heat recovery rates compared to RTOs, which can result in higher operational costs due to the need for supplemental fuel.

- Biofilters: Biofilters do not recover heat, making them less energy-efficient compared to thermal oxidizers.

Versatility and Application

-

RTOs: RTOs are versatile and can be used in various industries, including ethanol production, wood products, paint finishing, food processing, petrochemical, and pharmaceutical applications. They are effective in handling large volumes of air with high VOC concentrations.

-

Catalytic Oxidizers: These are typically used in applications where VOC concentrations are lower, and the presence of catalyst poisons is minimal.

- Biofilters: Biofilters are best suited for applications with low to moderate VOC concentrations and are commonly used in the food and beverage industry, wastewater treatment plants, and composting facilities.

Cost Comparison

Capital Costs

-

RTOs: The initial investment for RTOs can be high due to their complex design and the use of ceramic media beds. However, the long-term savings from energy efficiency and low operational costs can offset the higher capital costs.

-

Catalytic Oxidizers: These systems generally have lower capital costs compared to RTOs but may incur higher operational costs over time due to lower heat recovery efficiency.

-

Biofilters: Biofilters have the lowest capital costs among the three systems but may require more frequent maintenance and monitoring to ensure optimal performance.

Operational Costs

-

RTOs: Due to their high heat recovery efficiency, RTOs have lower operational costs. The need for minimal auxiliary fuel and reduced maintenance requirements contribute to cost savings.

-

Catalytic Oxidizers: Operational costs can be higher due to the need for supplemental fuel and potential catalyst replacement.

- Biofilters: While biofilters have low energy requirements, the costs associated with maintaining the biological media and ensuring proper airflow can add up.

Maintenance Costs

-

RTOs: With no moving parts and minimal maintenance requirements, RTOs are cost-effective in the long run.

-

Catalytic Oxidizers: These systems require regular monitoring and catalyst replacement, which can increase maintenance costs.

- Biofilters: Maintenance involves regular monitoring of biological media and ensuring optimal operating conditions, which can be labor-intensive.

When comparing air pollution control systems, RTOs offer superior performance and cost-effectiveness, particularly in applications with high VOC concentrations and stringent emission reduction requirements. Their high efficiency in emission reduction, energy efficiency through heat recovery, and low operational and maintenance costs make them a preferred choice for many industries. While catalytic oxidizers and biofilters have their own advantages, RTOs stand out as a versatile and reliable solution for comprehensive air pollution control.

For more information on how RTOs can benefit your operations, contact CECO or download our detailed brochure.