Odor Control in Bakeries

Beyond the Oven: Are RTOs the Secret Ingredient You’re Missing from Your Business?

One industry that often faces challenges related to Volatile Organic Compound (VOC) emissions and odor control is commercial bakeries. These applications release VOC-laden odors into the atmosphere, which can negatively impact human health and the environment, and cause strife in communities surrounding the facility. Adwest has over three decades of experience supporting these challenging applications with efficient and reliable odor control technologies.

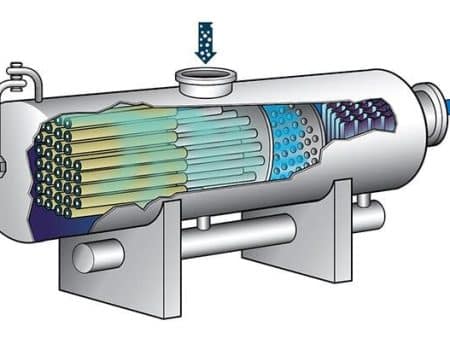

Adwest is a global leader in thermal and catalytic solutions for air pollution and odor control. They specialize in the custom designing and manufacturing of Regenerative Thermal Oxidizers (RTOs), VOC concentrators, Direct Fired Thermal Oxidizers (DFTOs), and catalytic oxidation solutions for industries worldwide. These systems are highly efficient at removing volatile organic compounds (VOCs), toxic fumes, odors, hydrocarbons, and hazardous air pollutants (HAPs), making industrial processes safer for the environment and community. RTOs are one of the most cost-effective and reliable technologies for efficient VOC abatement. These sophisticated systems not only excel in eliminating dangerous and odor-causing VOCs but also exhibit impressive Destruction and Removal Efficiency (DRE) rates, reaching up to 99% DRE.

The most common challenge that Adwest addresses in bakery applications is nuisance odor. Nuisance odor refers to unpleasant or offensive smells that are considered bothersome to individuals in a particular environment or location. These odors are often regulated by environmental protection agencies and laws. In the case of commercial bakeries, the smell of bread and other baked goods can be perceived as a nuisance odor by residents living in the surrounding neighborhoods. These odors are the result of the VOCs released during the fermentation and baking processes. The fermentation of yeast in bread production generates ethanol and other VOCs, which are released at high temperatures during baking. While the smell of freshly baked bread may be pleasant to some, the perception of odor is subjective, so it can become bothersome, especially if it becomes too intense or lingers in residential neighborhoods for extended periods. Strong, persistent, or frequent odors can lead to physical discomfort, annoyance, headaches, respiratory issues, and even psychological distress among affected individuals, as well as potential fines or potential shutdowns for the offending facility.

Volatile Organic Compounds (VOCs) released during the baking process contribute to the distinct aroma of yeast. The primary VOC emitted is ethanol, which is produced as a byproduct of yeast fermentation. Other VOCs, such as aldehydes and organic acids, can also contribute to the smell. Regulatory agencies and local authorities impose regulations and guidelines on bakery operations to address nuisance odors from commercial bakery emissions. These measures often involve limiting odor concentrations or requiring businesses or facilities to implement odor control technologies and practices. These regulations aim to protect the community and ensure that odor emissions are controlled to acceptable levels. Bakeries may be required to install odor control technologies, such as Catalytic Oxidizers or Regenerative Thermal Oxidizers (RTOs), which effectively remove VOCs and mitigate odor.

One such bakery in California was forced to confront this issue when they were notified of the need to install an RTO within a strict timeframe. They also required a customized ductwork system design, fabrication, and installation and turned to CECO Environmental for a solution.

The large bakery, running a 24/7 operation, faced potential fines and shutdown when the South Coast Air Quality Management District (SCAQMD) notified them that they were required to install an RTO unit to reduce VOC emissions from their bread ovens. With no availability for downtime and little schedule flexibility, they needed a system designed and installed quickly to process the exhaust from their bread ovens. Turnaround time and efficiency were key.

This challenge was significant, as the plant only shut down for a maximum of six hours every Friday. CECO Kirk & Blum, a leading global supplier of air pollution control technologies, was tasked with tying into seven existing oven exhaust stacks within the strict time frame while also designing and fabricating the necessary ductwork within two months of issuance of the purchase order.

To conquer this situation, CECO Kirk & Blum developed an “elbow cap” design that allowed the installation crew to tap into the seven stacks during the shutdown period and continue the installation while Gold Coast’s production commenced. The design, packaging, and installation of CECO Effox-Flextor-Mader dampers with a CECO Adwest RTO and control logic provided a complete solution that fit the bakeries’ urgent needs in the timeframe they required.

As a result of this innovative and collaborative approach, CECO accomplished the installation within the limited timeframe, achieving compliance with SCAQMD regulations. Additionally, the Adwest RTO unit reduced VOC emissions by approximately 504,000 pounds of ethanol annually, providing significant environmental and societal benefits.

CECO Environmental provided a dynamic, customizable solution, demonstrating the value of working with an experienced air pollution control technology provider. As more and more businesses face increasingly stringent regulations and environmental pressures, complete and total solutions like those provided by the CECO family brands are critical to maintaining compliance and reducing environmental impact.